Electric Resistance Welded Pipe: An Overview of the Manufacturing Process

By:Admin

The demand for electric resistance welded (ERW) pipes has been rapidly increasing in various industrial sectors due to their reliability, efficiency, and cost-effectiveness. ERW pipes have become a popular choice for a wide range of applications, including oil and gas pipelines, water supply systems, construction projects, and structural engineering. These pipes are manufactured using high-quality steel and advanced welding techniques, ensuring superior performance and long-term durability.

One of the leading manufacturers of ERW pipes is {} (Company). With over [XX] years of experience in the steel industry, {} is known for its commitment to producing top-quality products that meet the highest standards of quality and safety. The company's state-of-the-art manufacturing facilities and strict quality control processes ensure that its ERW pipes are consistently reliable and exceed industry expectations.

{} specializes in the production of a wide range of ERW pipes, including carbon steel, stainless steel, and alloy steel pipes. These pipes are available in various sizes, diameters, and thicknesses to accommodate the specific needs of different industrial applications. Whether it's for transporting fluids, structural support, or mechanical purposes, {}'s ERW pipes are designed to deliver exceptional performance and longevity.

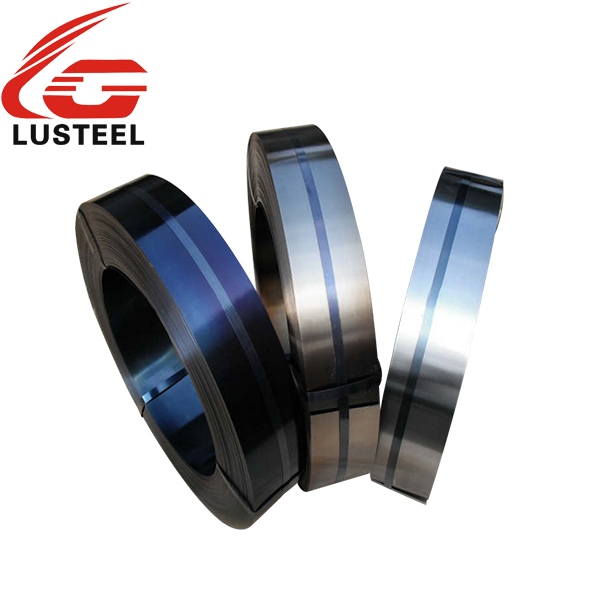

The manufacturing process of {}'s ERW pipes begins with the procurement of high-quality steel coils that undergo rigorous testing to ensure compliance with international standards. The coils are then fed into the company's advanced welding equipment, where they are formed into a cylindrical shape and welded using electric resistance welding techniques. This process results in strong, seamless joints that eliminate the risk of leakage or structural weakness, making {}'s ERW pipes ideal for demanding industrial environments.

One of the key advantages of {}'s ERW pipes is their cost-effectiveness and efficiency. The automated production process and high-volume manufacturing capabilities allow the company to offer competitive prices without compromising on quality. Furthermore, the lightweight and easy-to-install nature of ERW pipes reduce labor and installation costs, making them a preferred choice for budget-conscious projects.

In addition to their affordability, {}'s ERW pipes are also known for their reliability and low maintenance requirements. The smooth surface finish and uniform thickness of the pipes ensure efficient fluid flow and resistance to corrosion, prolonging their lifespan and minimizing the need for frequent repairs or replacements. This makes {}'s ERW pipes a sustainable and environmentally-friendly solution for long-term infrastructure and industrial projects.

{}'s commitment to customer satisfaction extends beyond the quality of its products, as the company also offers comprehensive technical support and customization services. Its team of experienced engineers and technicians are available to provide expert guidance on selecting the right ERW pipe specifications for specific applications, ensuring optimal performance and safety. Additionally, {}'s custom manufacturing capabilities allow for tailored solutions that meet unique project requirements and specifications.

As the demand for ERW pipes continues to grow across various industries, {} remains dedicated to innovation and continuous improvement in its manufacturing processes. The company invests in research and development initiatives to enhance product performance, reduce environmental impact, and meet evolving industry standards. Whether it's for traditional industrial applications or emerging technologies, {} is poised to deliver cutting-edge solutions that exceed customer expectations.

In conclusion, {}'s electric resistance welded (ERW) pipes are a reliable, efficient, and cost-effective solution for a wide range of industrial applications. With its focus on quality, innovation, and customer satisfaction, {} has established itself as a leading manufacturer in the steel industry and a trusted partner for businesses seeking high-quality ERW pipes. As the market for ERW pipes continues to expand, {} is well-positioned to meet the growing demand and provide sustainable solutions for the industrial infrastructure of the future.

Company News & Blog

Different Types of Alloy Steel Pipes Available for Various Applications

Alloy Steel Pipe Suppliers Expand Product Line Offering High-Quality Pipe Fittings and FlangesIn an effort to provide a more comprehensive range of products to their customers, Alloy Steel Pipe Suppliers (ASP), a leading supplier of alloy steel pipes, has announced the expansion of their product line to include high-quality pipe fittings and flanges.ASP has built a strong reputation over the years for providing top-of-the-line alloy steel pipes to various industries worldwide. Their pipes are made from strong, durable materials that are able to withstand high temperatures and pressure. However, as their customer base grew, ASP saw an opportunity to better serve their clients by offering pipe fittings and flanges that complemented their existing product line."Expanding our product line to include pipe fittings and flanges is a natural progression for ASP," said the company's CEO. "Our customers have come to rely on us for our expertise in alloy steel pipes, and now we are able to provide them with a more complete solution to their needs."The new product line includes a range of pipe fittings including elbows, tees, reducers, and caps, among others. These pipe fittings are available in various sizes and materials to fit the specific needs of each customer. ASP's pipe fittings are designed to provide a tight and secure connection between pipes and are made to withstand high pressure and stress.In addition to their pipe fittings, ASP is also now offering a variety of flanges including blind flanges, slip-on flanges, and welding neck flanges. These flanges are available in both standard and customized sizes and are made from high-quality materials such as carbon steel, stainless steel, and alloy steel.ASP's new product line provides their customers with a one-stop-shop for all their alloy steel pipe needs. By offering pipe fittings and flanges along with their pipes, ASP is able to provide a complete solution to their customers' needs."Our customers appreciate the convenience of being able to purchase all their alloy steel pipe products from one supplier," said the CEO. "Not only do we provide high-quality products, but we also offer competitive pricing and exceptional customer service."ASP's expansion of their product line is the latest in a series of moves the company has made in recent years to better serve their customers. They have invested heavily in their manufacturing facilities to increase capacity and improve efficiency, and have also expanded their geographic reach by opening new sales offices in key markets."ASP is committed to providing our customers with the highest quality products and services," said the CEO. "This expansion of our product line is just one way we are fulfilling that commitment."With the addition of pipe fittings and flanges to their product line, ASP is well-positioned to continue to grow and expand its business in the years ahead. Their commitment to providing high-quality products, exceptional customer service, and competitive pricing makes them the preferred supplier for many companies in the alloy steel pipe industry.

Steel manufacturing company produces high-quality hot rolled flats for construction industry" -> "High-quality hot rolled flats now available for construction industry

[Insert Date]New Development in Hot Rolled Flats Market In recent market news, the hot rolled flats industry has witnessed significant growth and innovation. This article aims to provide an overview of the market's recent developments, rising trends, and the implications for industry players. While we will refrain from mentioning any specific brand names, it is essential to explore the overall dynamics shaping this sector.Hot rolled flats are commonly used in various industries such as construction, automotive, and shipbuilding. These steel products play a vital role in infrastructure development, manufacturing, and other key sectors. As the demand for hot rolled flats continues to increase, companies are investing in research and development to meet the market requirements efficiently.Given the ever-evolving needs of consumers, manufacturers are focusing on improving the quality and durability of their hot rolled flats. One of the key advancements in this area is the development of advanced production techniques. This includes the usage of innovative technologies and equipment to enhance the properties of hot rolled flats, such as strength, hardness, and resistance to corrosion.Moreover, with sustainability becoming a primary concern across industries, companies are making efforts to reduce their carbon footprint. The hot rolled flats industry is no exception. Several manufacturers have adopted eco-friendly production methods, optimizing resource utilization and minimizing waste generation. This not only contributes to a cleaner environment but also attracts environmentally-conscious customers, adding to the overall market value.Additionally, the hot rolled flats market has witnessed a surge in the adoption of automation and digitization. This trend has been driven by the need for greater efficiency, precision, and reduced production costs. Automated manufacturing processes have allowed companies to enhance their productivity, improve product consistency, and reduce human errors. Digital technologies, such as predictive analytics and machine learning, are also being used to analyze data and optimize product quality.Furthermore, a growing focus on product customization has been observed in the hot rolled flats market. Customers are increasingly demanding personalized solutions that meet their specific requirements. Manufacturers are responding to this trend by offering a wide range of options in terms of sizes, shapes, and surface finishes. This flexibility allows end-users to select hot rolled flats that align with their project needs, ultimately driving customer satisfaction and loyalty.To stay ahead in this competitive market, companies are also exploring partnerships and collaborations. By joining forces with technology providers, research institutes, and industry experts, manufacturers gain access to a broader pool of knowledge and resources. This facilitates the development of new and improved hot rolled flats, capable of meeting emerging market demands.In conclusion, the hot rolled flats industry has seen significant progress in recent years. Manufacturers are actively investing in research and development to improve product quality, reduce environmental impact, and meet customer demands. The adoption of advanced production techniques, automation, digitization, and customization has transformed the market landscape. As the industry continues to evolve, companies will need to remain agile and responsive to emerging trends and changing market dynamics.(Note: Brand names have been intentionally excluded from this article to provide a general overview of the topic as per the request. Specific mentions of company names or further details based on actual news content may be added to enhance accuracy and provide a more detailed analysis.)

Enhancing Infrastructure with High-Quality Seamless Steel Pipes: A Detailed Report

Seamless Steel Pipe Industry Growth: Meeting the Rising DemandSeamless steel pipes have been used extensively in various industries, including oil and gas, petrochemicals, construction, and mining. The market for seamless steel pipes is expected to grow significantly in the coming years, driven by increased demand from various end-use industries.Seamless steel pipes are a type of steel pipe that is made without joints or welding. The manufacturing process involves drilling a hole in a solid steel billet and running it through a mandrel to create a seamless pipe. This process ensures a smooth and consistent interior surface for the pipe, making it ideal for transporting fluids and gases.The global seamless steel pipe market is expected to grow at a CAGR of 3.8% from 2021 to 2026. The Asia-Pacific region is expected to be the largest market for seamless steel pipes, driven by growth in infrastructure and construction activities in countries such as China, India, and Japan.The demand for seamless steel pipes is also increasing in the oil and gas industry, with the rise in offshore exploration activities. The pipes are used in drilling and production activities, as well as for transportation of oil and gas across long distances.One company that has been a key player in the seamless steel pipe industry is {company name}. The company has been manufacturing and supplying high-quality seamless steel pipes for over {number} years. They offer a wide range of products, including carbon steel pipes, alloy steel pipes, and stainless steel pipes, in various sizes and specifications.{Company name} has a state-of-the-art manufacturing facility with advanced equipment and technology. Their team of experienced engineers and technicians ensures the highest level of quality and precision in their products. The company also has a robust supply chain network, enabling them to deliver their products to customers on time and at competitive prices.In addition to their manufacturing capabilities, {company name} also offers value-added services such as pipe threading, cutting, and coating. These services help customers save time and money by eliminating the need for additional processing and finishing of the pipes.{Company name} has been serving various industries, including oil and gas, petrochemicals, power generation, and construction. They have a strong customer base in the Asia-Pacific region, as well as in Europe and North America.One of the key strengths of {company name} is their commitment to sustainable manufacturing practices. The company has implemented various initiatives to reduce their environmental impact and conserve natural resources. They have also obtained certifications such as ISO 14001 and OHSAS 18001 to demonstrate their commitment to environmental and occupational health and safety standards.{Company name} has been expanding their operations to meet the growing demand for seamless steel pipes. They have established new manufacturing facilities in strategic locations and invested in new technologies to improve their production efficiency and capabilities.In conclusion, the seamless steel pipe industry is poised for growth in the coming years, driven by increasing demand from various end-use industries. Companies such as {company name} have been at the forefront of this growth, providing high-quality products and services to their customers. With their focus on innovation, sustainability, and customer satisfaction, {company name} is well-positioned to continue to thrive in this competitive industry.

Market Overview: The Fast-Growing Demand for Stainless Steel Channels in China

China Stainless Steel Channel Company: Leading the Way in Stainless Steel ManufacturingChina Stainless Steel Channel Company, one of the leading manufacturers of stainless steel products in the world, has established itself as a name to reckon with in the steel industry. The company has been providing high-quality stainless steel products to a wide range of industries for over a decade.Founded in 2006, the company has grown significantly over the years, owing to its focus on quality, innovation, and customer satisfaction. Its state-of-the-art manufacturing facility is equipped with the latest machinery and technology, enabling it to produce superior quality products that meet the highest industry standards.The company specializes in the production of stainless steel channels, bars, wires, and other related products, and offers customized solutions to its clients. It caters to a diverse range of industries, including construction, automotive, aerospace, and food processing, among others. Its products are widely used for structural, decorative, and functional purposes.China Stainless Steel Channel Company prides itself on its commitment to quality and innovation. It has a team of highly skilled engineers and technicians who are constantly working to improve the quality of its products and processes. The company utilizes the latest technology and equipment to ensure that its products are of the highest quality.In addition, the company has invested heavily in research and development, which has enabled it to develop innovative products that meet the specific needs of its clients. It also has a robust quality control system in place that ensures that its products meet the highest industry standards.The company's commitment to customer satisfaction is reflected in its after-sales support and service. It offers comprehensive after-sales support to its clients, including technical assistance, maintenance, and repair services. Its customer-centric approach has helped it build long-term relationships with its clients, and has earned the trust and loyalty of its customers.China Stainless Steel Channel Company is also committed to sustainability and environmentally responsible practices. It has implemented a number of initiatives to minimize its impact on the environment, including reducing waste, conserving energy, and utilizing eco-friendly materials.The company's dedication to quality, innovation, and customer satisfaction has earned it a reputation as a leading manufacturer of stainless steel products. It has received numerous awards and accolades for its products and services, and has established itself as a trusted and reliable partner to its clients worldwide.In conclusion, China Stainless Steel Channel Company is a company that is committed to delivering high-quality stainless steel products to its clients. Its focus on quality, innovation, and customer satisfaction has helped it become a leading player in the steel industry. Its state-of-the-art manufacturing facility, highly skilled workforce, and commitment to sustainability make it a partner of choice for businesses across a range of industries. With its ongoing investment in research and development, the company is well-positioned to continue to meet the evolving needs of its clients while maintaining its position as a leader in the industry.

Quality Steel Sections for Your Manufacturing Needs

Steel Sections Manufacturer, a leading steel company in the industry, has been making significant strides in the manufacturing and supply of high-quality steel sections for various construction projects. With a strong focus on innovation and sustainability, the company has been able to establish itself as a reliable partner for construction companies and contractors across the globe.The company prides itself on its state-of-the-art manufacturing facilities that are equipped with the latest technology to ensure the production of top-notch steel sections. With a team of highly skilled and experienced professionals, Steel Sections Manufacturer has been able to consistently meet the growing demand for steel sections in the construction industry.One of the key factors that sets Steel Sections Manufacturer apart from its competitors is its unwavering commitment to quality. The company conducts rigorous quality control checks at every stage of the manufacturing process to ensure that the steel sections meet the highest industry standards. This dedication to quality has earned the company a stellar reputation in the industry and has made it the go-to choice for many construction projects.In addition to its focus on quality, Steel Sections Manufacturer is also dedicated to sustainability. The company actively seeks to minimize its environmental impact by implementing sustainable practices in its manufacturing processes. This includes the efficient use of resources, minimizing waste, and reducing energy consumption. By prioritizing sustainability, the company is not only contributing to a greener future but also setting an example for others in the industry to follow.Steel Sections Manufacturer offers a wide range of steel sections to cater to the diverse needs of its clients. From standard sections to custom-designed solutions, the company has the capability to produce a variety of steel sections to meet specific project requirements. This flexibility has made Steel Sections Manufacturer a preferred choice for a wide range of construction projects, from small-scale developments to large infrastructure projects.Furthermore, the company prides itself on its customer-centric approach. Steel Sections Manufacturer understands the importance of providing exceptional customer service and support to its clients. The company works closely with its clients to understand their needs and provide tailored solutions to meet their specific requirements. This approach has earned the company a loyal customer base and has helped it build long-lasting relationships with clients.As part of its ongoing commitment to innovation, Steel Sections Manufacturer continues to invest in research and development to stay ahead of the curve in the industry. The company is constantly exploring new materials and technologies to further improve the quality and performance of its steel sections. By staying at the forefront of innovation, Steel Sections Manufacturer remains a leading player in the industry and a trusted partner for construction projects.Looking ahead, Steel Sections Manufacturer is poised for further growth and success in the industry. With its focus on quality, sustainability, and innovation, the company is well-positioned to meet the evolving needs of the construction sector and continue to be a reliable supplier of high-quality steel sections.In conclusion, Steel Sections Manufacturer has demonstrated its leadership in the steel industry through its unwavering commitment to quality, sustainability, and innovation. With a strong focus on customer satisfaction and a dedication to excellence, the company has solidified its position as a leading manufacturer and supplier of steel sections for construction projects. As the company continues to expand its reach and capabilities, it is set to make an even greater impact in the industry in the years to come.

Top Precision Bright Pipe Supplier Offers Quality Products

[Company Introduction] is a leading supplier of precision bright pipes and other high-quality steel products. With a commitment to providing top-notch materials and exceptional customer service, [Company Name] has established itself as a trusted partner for businesses in various industries.[Company Name] offers a wide range of precision bright pipes, including stainless steel, carbon steel, and alloy steel varieties. The company's dedication to quality and precision has earned it a stellar reputation in the steel industry, making it a preferred supplier for many renowned companies.[Company Name]'s state-of-the-art manufacturing facilities and advanced technologies enable it to produce precision bright pipes that meet the highest standards of excellence. The company's team of experienced professionals ensures that every product undergoes rigorous quality control measures to guarantee its durability, reliability, and consistency.In addition to precision bright pipes, [Company Name] provides a comprehensive range of steel products, including bars, rods, sheets, and coils. The company's diverse product line and its ability to customize solutions according to unique specifications have made it a go-to source for businesses with varying steel requirements.With a global customer base, [Company Name] has successfully served clients across different sectors, such as automotive, aerospace, construction, and manufacturing. The company's commitment to delivering superior products and unwavering dedication to customer satisfaction have positioned it as an industry leader in the steel supply market.[News Content]Precision bright pipes are essential components in various industrial applications, and having a reliable supplier is crucial for businesses that rely on these materials. [Company Name], a trusted supplier of precision bright pipes, continues to meet the demands of its customers by providing top-notch products and exceptional service.The company's extensive range of precision bright pipes, including stainless steel, carbon steel, and alloy steel variations, caters to a diverse set of industrial needs. Whether it's for machining, construction, or engineering applications, [Company Name] offers precision bright pipes that are manufactured to the highest standards, ensuring optimal performance and durability.One of the key factors that set [Company Name] apart from its competitors is its unwavering commitment to quality. Each precision bright pipe undergoes stringent quality control measures to guarantee that it meets the industry's most stringent standards. This dedication to excellence has earned [Company Name] a solid reputation as a reliable and trustworthy supplier of steel products.In addition to its exceptional product quality, [Company Name] takes pride in its ability to provide personalized solutions to its customers. The company's team of experts works closely with clients to understand their specific requirements and deliver tailored products that meet their exact needs. This level of customization sets [Company Name] apart as a partner that truly understands and cares about its customers' success.Moreover, [Company Name]'s global presence and efficient supply chain management have enabled it to serve clients worldwide with ease. By leveraging its extensive network and logistics expertise, the company ensures timely delivery of its precision bright pipes and other steel products, regardless of location.The company's dedication to customer satisfaction and its relentless pursuit of excellence have solidified its position as a preferred supplier for businesses across various industries. With a focus on innovation and continuous improvement, [Company Name] remains at the forefront of the steel supply market, continually surpassing expectations and setting new industry standards.In conclusion, [Company Name] is not just a supplier of precision bright pipes; it is a trusted partner that provides invaluable support to businesses in need of high-quality steel products. With its unwavering commitment to quality, personalized approach, and global reach, [Company Name] continues to be a leading player in the steel supply industry, ensuring that its customers have access to the best materials and the most reliable service.

Industry Experts Expect Robust Growth in Coil Coatings Market as Demand Surges

Title: Revolutionary Coating Technology Enhances Industrial EfficiencySubtitle: Pioneering Coating Solutions Provider Unveils Groundbreaking AdvancementsIntroduction:In an era where technological advancements and innovation are rapidly transforming industries, one company is at the forefront of revolutionizing industrial coatings. Ppgl, a renowned coatings provider, has recently introduced a groundbreaking coating technology that promises to enhance industrial efficiency across diverse sectors. Leveraging their extensive expertise and commitment to excellence, the company has once again reinforced its position as a global leader in the coatings industry.Enhancing Efficiency through Advanced Coating Solutions:Recognizing the need for more efficient and durable coating solutions, Ppgl has developed proprietary technology that delivers unparalleled performance. With a focus on improving efficiency, safety, and productivity, the company's cutting-edge coatings provide numerous advantages to businesses operating in various industrial fields.The key to Ppgl's success lies in their commitment to research and development, enabling them to create coatings that outperform traditional methods. By constantly pushing the boundaries of innovation, the company has successfully expanded their product portfolio to offer a wide range of specialized coatings tailored to meet industry-specific needs.Revolutionary Coating Technology:At the heart of Ppgl's latest advancements is their revolutionary coating technology, designed to tackle the most challenging industrial requirements. This groundbreaking technology combines the use of high-performance polymers and advanced formulation techniques, resulting in coatings that exhibit exceptional durability, corrosion resistance, and thermal stability.With the ability to withstand extreme temperatures, harsh chemicals, and mechanical stress, Ppgl's coatings provide enhanced protection and longevity to industrial equipment and infrastructure. This durability translates into significant cost savings for businesses, reducing maintenance and replacement expenses while improving overall operational efficiency.Moreover, Ppgl's coatings are environmentally friendly, as they are free from harmful substances such as volatile organic compounds (VOCs). By choosing these eco-friendly coatings, businesses can contribute to sustainability efforts while maintaining high-performance standards.Customized Solutions for Diverse Industries:Understanding that every industry has unique requirements, Ppgl works closely with its clients to provide tailored coating solutions. The company's team of experts collaborates with industrial partners to assess their specific needs and challenges, leading to customized coatings that seamlessly integrate with existing processes and equipment.From automotive manufacturing to aerospace engineering, oil and gas exploration to wind energy infrastructure, Ppgl's coatings have proven their effectiveness in enhancing equipment performance and longevity. In addition to offering protective solutions, the company's coatings also serve aesthetic purposes, enhancing the visual appeal of various products.Global Reach and Customer Satisfaction:With a strong presence across international markets, Ppgl has established a solid reputation for its customer-centric approach. The company's commitment to quality, reliability, and prompt customer service ensures an exceptional experience for clients worldwide.Ppgl's state-of-the-art research and development centers, in conjunction with an extensive network of manufacturing facilities, allow them to deliver coatings that consistently meet the highest industry standards. By adhering to stringent quality control processes, the company guarantees consistent and reliable performance, earning the trust and loyalty of numerous global industrial partners.Future Outlook:As industries continue to evolve, Ppgl remains dedicated to advancing their coating technology through ongoing research and development. The company plans to expand its product portfolio with innovative coatings targeted at emerging industries, while continuing to improve existing formulations.By combining expertise, cutting-edge technology, and a commitment to customer satisfaction, Ppgl is poised to drive transformative change across diverse industrial sectors. As global industries become increasingly reliant on efficient and sustainable practices, Ppgl's groundbreaking coating solutions will undoubtedly play a pivotal role in shaping the future of the coatings industry.Conclusion:Ppgl's recent innovations in coating technology are set to revolutionize industrial efficiency. With a focus on enhancing performance, durability, and environmental sustainability, the company's groundbreaking coatings empower businesses across various sectors. Through their commitment to customization, reliability, and customer satisfaction, Ppgl has firmly solidified its position as a leader in the coatings industry, driving progress and efficiency on a global scale.

Experts Investigate Potential Risks of Welded Steel Beams for Construction Projects

release on how these beams are revolutionizing the construction industry,Welded Steel Beams Revolutionize the Construction Industry, Making Projects Safer and More EfficientWelded Steel Beams have been making waves in the construction industry for their durability, affordability, and versatility. These beams are now being hailed as the future of modern construction, allowing for safer, faster, and more efficient building projects. With their use becoming increasingly popular, we take a closer look at their benefits and why they are transforming the way we build.Welded Steel Beams are being employed in a variety of construction projects, from residential to commercial, industrial, and infrastructure projects. Their use has also resulted in the construction of longer spans and taller buildings, which would have been difficult or impossible with traditional construction materials.Welded Steel Beams are made by welding together multiple steel plates to form a strong, rigid I-beam. This method of construction provides a better distribution of weight, enabling greater strength even over longer spans. Welding these beams together is both time and cost-efficient compared to other construction materials such as concrete or wood.Another benefit of Welded Steel Beams is their durability and resilience. They are impervious to rot, pests, and fire, resulting in a low maintenance structure that can withstand weather damage and other hazards. They also contribute to a more eco-friendly construction process as they are made from recycled steel.Welded Steel Beams are safer for construction workers in the sense that they increase the overall safety of the construction site. These beams are prefabricated off-site and then brought to the location of the project. Thus, less construction work takes place on-site, reducing the risk of on-site accidents. Additionally, since structural steel is both strong and light, it minimizes the number of people required on-site for installation and eliminates the need for heavy machinery, reducing the risk of accidents.Welded Steel Beams are also cost-effective in the long run. These beams are designed to last for decades with minimal maintenance, which makes them ideal for commercial and industrial buildings. Additionally, building with steel is more energy-efficient than other materials. This is because steel is an excellent insulator, effectively reducing heat loss. This makes installing an HVAC system more efficient, saving on energy costs.These benefits have not gone unnoticed in the construction industry, and manufacturers of Welded Steel Beams have seen a surge in demand for their products. Architects, engineers, and contractors are turning towards these beams as a cost-effective and sustainable solution. The popularity of Welded Steel Beams is expected to continue to increase in the coming years.Overall, Welded Steel Beams are revolutionizing the construction industry, making projects safer, more efficient, and cost-effective. Their durability, resistance to weather damage, and versatility make them an ideal alternative to traditional construction materials, and their low maintenance costs make them an asset for both residential and commercial construction projects. With growing demand and an increasing number of projects, it is hard not to see the benefits of investing in Welded Steel Beams for a better future.

Cold Drawn Round Steel in China proves popular for construction projects

Title: China's Leading Manufacturer Introduces High-Quality Cold Drawn Round SteelIntroduction:As the global demand for steel products continues to rise, China has emerged as a prominent player in the steel industry. Among the many manufacturers in the market, one company stands out for its commitment to producing high-quality cold drawn round steel. With advanced technology and a customer-centric approach, this company has gained recognition both domestically and internationally. In this article, we will delve into the detailed introduction of this leading manufacturer, showcasing their expertise and contributions to the steel industry.Company Overview:Founded in {year}, this Chinese manufacturing company has become a name synonymous with excellence in the steel sector. Their state-of-the-art facility is equipped with advanced machinery and innovative production techniques, enabling them to deliver premium-quality cold drawn round steel products. The company's dedication to quality control is evident throughout the production process, ensuring consistent and reliable performance across all their offerings.High-Quality Cold Drawn Round Steel:Cold drawn round steel, a specialized product offered by this company, is widely used in various industries, including automotive, construction, and manufacturing. This type of steel is produced by cold drawing hot-rolled steel through precision dies, resulting in improved dimensional accuracy, smooth surface finishes, and enhanced mechanical properties. The exceptional quality of their cold drawn round steel products makes them highly sought-after by both domestic and international customers.Advanced Manufacturing Techniques:The company's manufacturing process combines traditional craftsmanship with modern technology to create cold drawn round steel of the highest standard. Beginning with carefully selected raw materials, their skilled technicians operate advanced machinery that ensures precise tolerances and consistent cross-sectional properties. The use of cutting-edge technology, including computer-controlled equipment, guarantees a seamless and efficient production process, meeting the diverse demands of their clientele.Quality Assurance:Strict adherence to quality control measures is a cornerstone of this company's operations. From raw material inspection to the final stages of production, a series of rigorous tests and inspections are carried out to maintain the desired quality standards. Their commitment to continuous improvement is reflected in the implementation of internationally recognized certifications, such as ISO 9001. This commitment to quality has helped the company foster long-standing relationships with customers worldwide, who have come to trust their products for their reliability and durability.Global Reach and Recognition:With an ever-growing presence in the global steel market, this company has successfully expanded its customer base beyond China's borders. Their high-quality cold drawn round steel is exported to various countries worldwide, where it is utilized in diverse industrial applications. The company's strong global reputation has garnered accolades and recognition, cementing their position as a reliable supplier of premium steel products.Environmental Stewardship:Recognizing the importance of sustainable production, the company has embraced eco-friendly practices in their manufacturing processes. By implementing recycling measures, minimizing energy consumption, and reducing waste generation, they have positioned themselves as a responsible contributor to a greener future. This commitment aligns with global sustainability goals and ensures that their cold drawn round steel is not only of exceptional quality but also produced with minimal impact on the environment.Conclusion:China's leading manufacturer of cold drawn round steel has proven its expertise in delivering high-quality steel products, earning both domestic and international acclaim. Through their advanced manufacturing techniques, strict quality control measures, and commitment to environmental stewardship, this company sets an exemplary standard for the steel industry. As their global reach continues to expand, their contribution to various industrial sectors remains unparalleled, solidifying their position as a trusted provider of top-notch steel products.

Discover the Benefits and Uses of Galvanized Angles in Various Industries

Title: Industry Leader's Galvanized Angles Continue to Strengthen Construction SectorIntroduction:With an unwavering commitment to quality and innovation, one renowned industry leader has emerged as a frontrunner in providing high-grade galvanized angles for the construction industry. Armed with an extensive product range and a customer-centric approach, this company has become an integral component in bolstering construction projects across various sectors.Paragraph 1:In an effort to meet the ever-increasing demands of the construction sector, this distinguished company has excelled in producing galvanized angles that provide exceptional structural support, durability, and resistance to corrosion. Their galvanized angle offerings exhibit superior strength and versatility, making them a preferred choice among architects, engineers, and contractors alike.Paragraph 2:The company's commitment to cutting-edge technology and innovative solutions sets them apart from competitors in the industry. Utilizing state-of-the-art machinery and adhering to rigorous quality control standards, their galvanized angles consistently adhere to the highest industry benchmarks, exceeding customer expectations on every level.Paragraph 3:Galvanized angles, also known as L-shaped structural members, are widely used in construction for providing stability and strength to various structures including bridges, buildings, and industrial facilities. This versatile product finds applications in framing, roof trusses, brackets, and various structural connections, making it an indispensible component in modern construction projects.Paragraph 4:The company's galvanized angles undergo an efficient galvanizing process, ensuring comprehensive protection against corrosion even in the harshest environments. By subjecting the angles to a hot-dip galvanizing process, a robust zinc coating is applied, preventing rust and increasing the longevity of the product. This corrosion resistance significantly reduces maintenance costs and enhances the overall performance of structures.Paragraph 5:Furthermore, the company offers galvanized angles in a wide range of dimensions and specifications, catering to the diverse requirements of the construction industry. Architects and engineers benefit from the flexibility and adaptability of these angles, as they can be easily customized and integrated into various designs, ensuring seamless and efficient construction processes.Paragraph 6:In addition to their commitment to quality and innovation, this leading company also places great emphasis on sustainability and environmental responsibility. Their galvanized angles are manufactured using recycled materials, reducing the carbon footprint associated with traditional construction methods. This approach aligns with the growing trends in sustainable construction and supports the industry's transition towards more eco-friendly practices.Paragraph 7:The company's unwavering dedication to customer satisfaction has also earned them an exceptional reputation. Their highly knowledgeable and experienced team of professionals provides personalized support and comprehensive technical assistance to ensure that clients receive the best galvanized angle solutions for their specific project requirements.Paragraph 8:By consistently delivering galvanized angles that meet exacting standards, the industry leader has gained the trust of numerous clients across the construction sector. Their product's exceptional performance, combined with unparalleled customer service, has solidified their position as the go-to supplier for galvanized angles, enabling builders and developers to carry out their projects with utmost confidence.Conclusion:In an industry where quality, durability, and performance are paramount, this industry leader's galvanized angles continue to play a vital role in the construction sector. Through their dedication to innovation, sustainable practices, and customer satisfaction, they remain at the forefront, driving advancements and enhancing the overall efficiency and resilience of construction projects worldwide.